What it solves

Milling operations often run with fragmented data, delayed reporting, and limited downtime visibility. plantrun brings the key metrics and the operational context into one place, so teams can act with confidence.

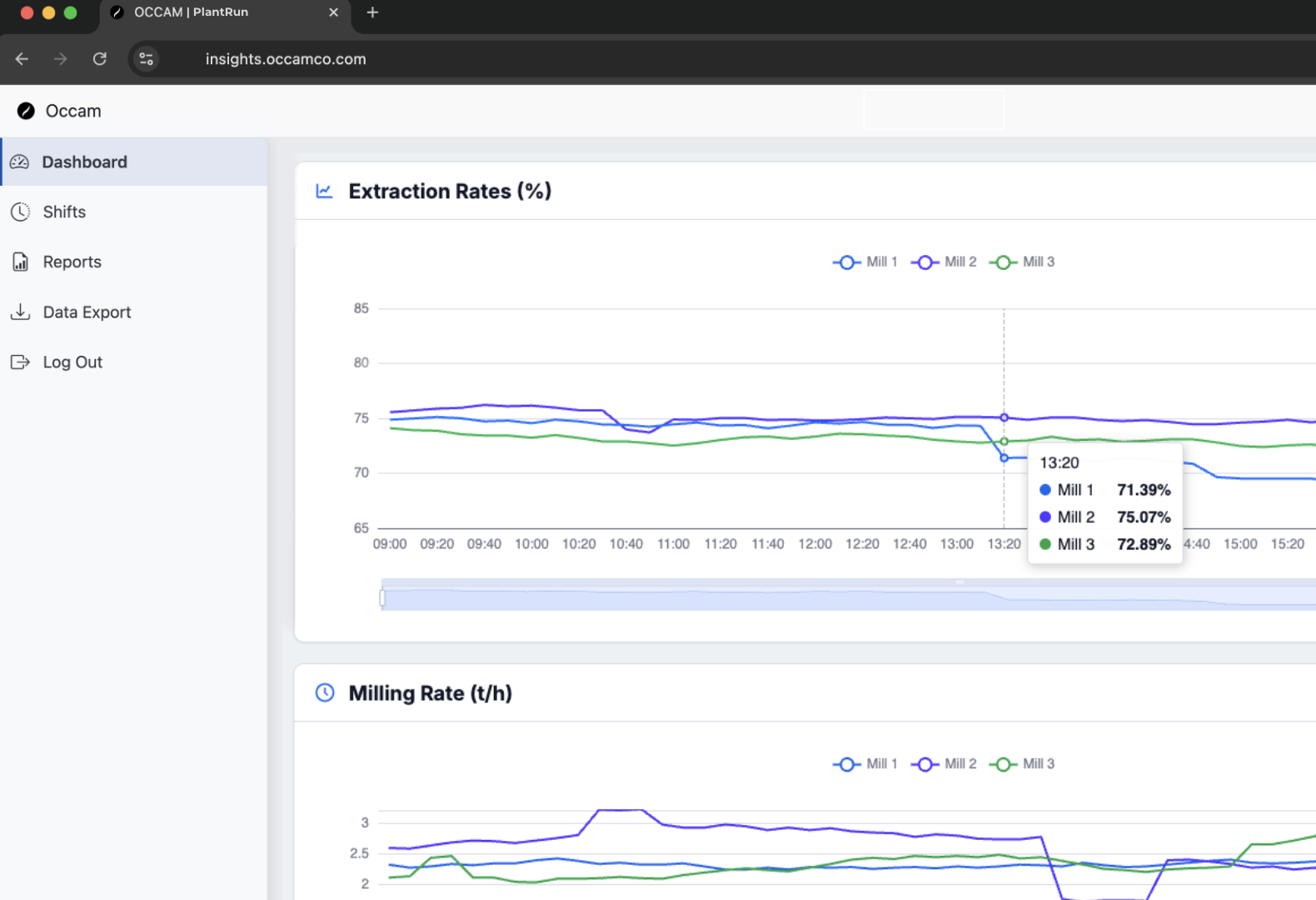

Operational visibility

Extraction, milling rates, shift performance, and production totals in a single view.

Downtime clarity

Track stoppages by event count and minutes, tied to specific equipment and causes.

Decision support

Daily, weekly, and monthly reporting with AI-driven summaries to highlight what matters.

Core capabilities

Everything is designed to answer two questions: how is the mill running, and what needs attention next.

- Live dashboard with extraction rates, milling rates, recent shift downtime, and production totals across products.

- Downtime analytics showing events and minutes down, with drill-down by equipment and cause.

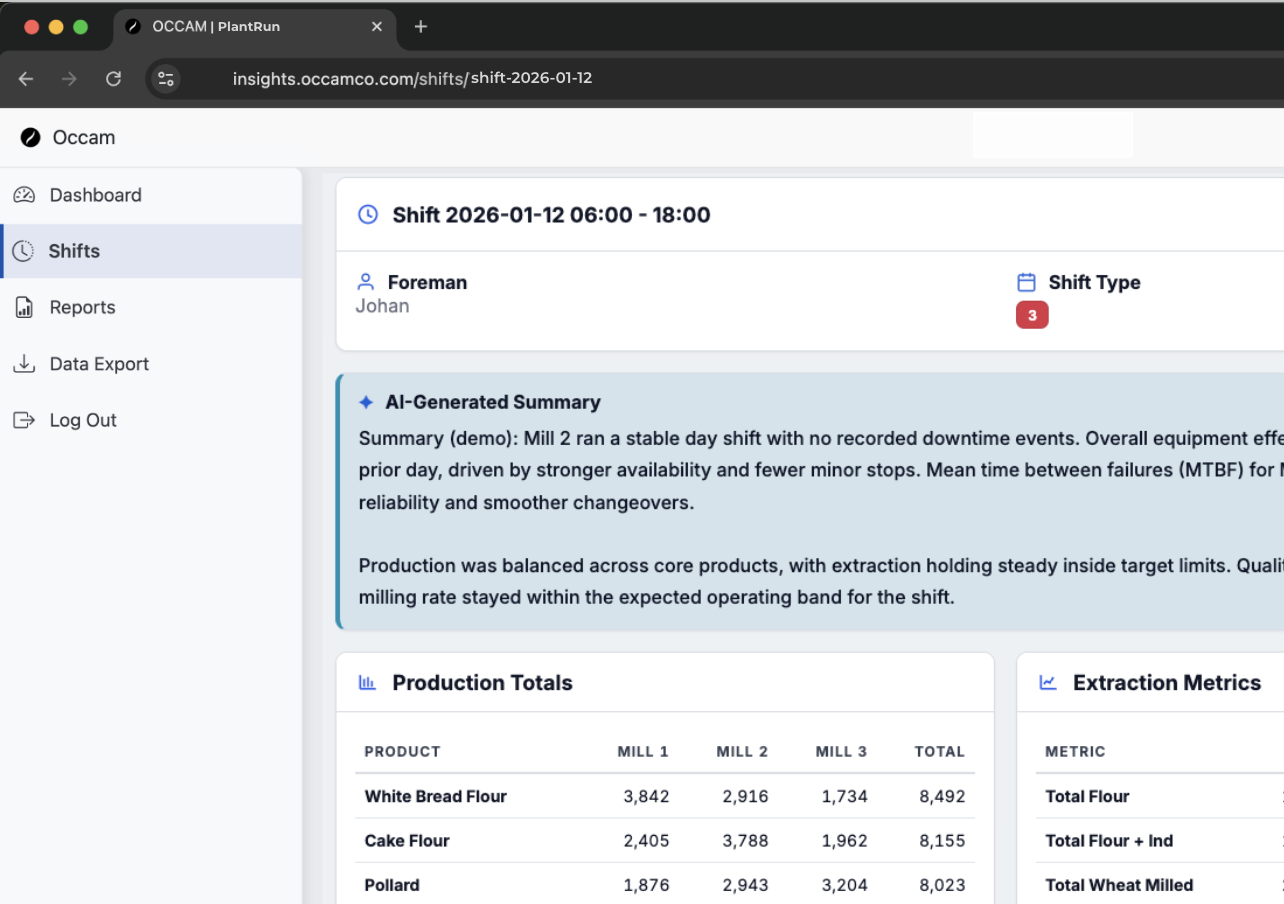

- Shift module for foremen to log what happened, when it happened, and which equipment was affected.

- Maintenance event logging for planned and unplanned work, including comments and supporting context.

- Daily, weekly, and monthly reports with clear visuals and control-limit style views where relevant.

- AI analysis that summarises key patterns and exceptions so management can scan and move.

- Data export of shift-level detail to CSV for audits, deeper analysis, or integration.

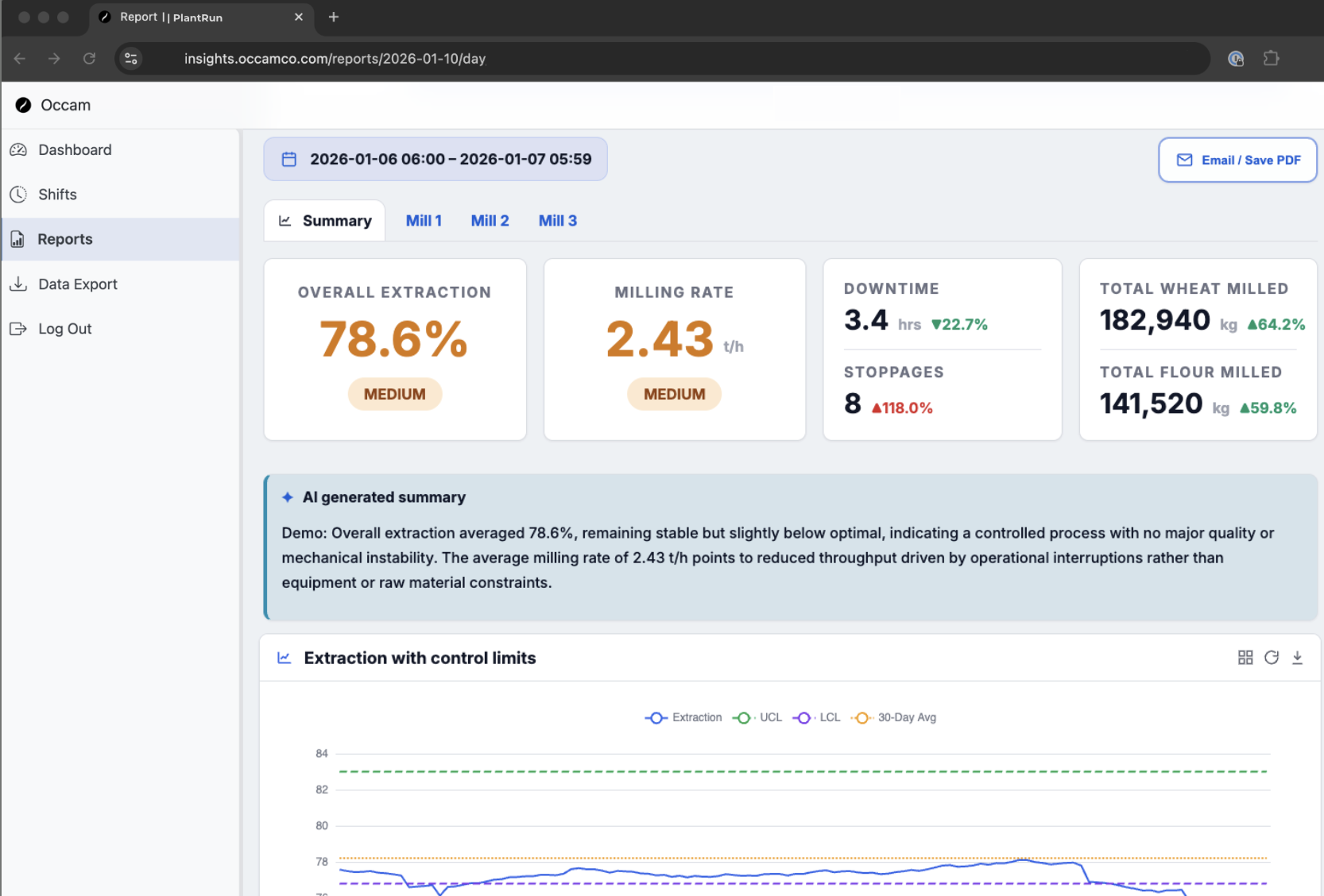

Reporting that people actually use

Reports are built to be shared, acted on, and traced back to source. Each report includes the metrics, the narrative, and the underlying data when needed.

- Daily report covering extraction and milling performance, downtime, and key exceptions.

- Weekly and monthly views to track trends and improvement over time.

- Control-limit style monitoring to spot drift early and reduce reactive firefighting.

- AI summary that highlights what changed, why it matters, and where to look.

How it fits into a multi-product mill

plantrun is designed for mills producing multiple product lines. Production totals, extraction metrics, and reporting can be segmented by product, model, shift, and time window.

Multi-product production

Track product outputs side by side and understand what each shift delivered.

Extraction context

Monitor total flour, total wheat milled, and extraction trends over time.

Operational truth

Every metric links back to shift capture and equipment-level events for traceability.

Built for action, not just dashboards

You already send a daily report. The next step is exception-based communication so the right people know when something is off, immediately.

- Threshold alerts when extraction, milling rate, downtime, or other key metrics exceed agreed limits.

- WhatsApp-style notifications to notify relevant roles when action is required.

- Escalation rules to route persistent issues to the right level.

Note: the alerting module can be enabled only where it makes operational sense, and tuned with your team.

Want to see it with your data?

We will walk you through the platform, map it to your process, and show what a rollout could look like. If it is not a fit, you will know quickly.

Typical first session: 30 to 45 minutes. No hard sell, just an honest view of value and effort.